Pumps

Vertical Turbine Barge

Bayou City Pump Company, a service and manufacturing company founded in 1973, has been a leader in repairing and refurbishing services for many of the major barge transportation companies operating in the United States. With over 34 years of dedicated experience repairing and servicing vertical turbine pumps, Bayou City Pump Company provides the best offering of products and services to the market place. We are a true 24/7 company providing service, products and spare parts anytime, anyplace.

Designed specifically for liquid barge transfer operations, the Bayou City Pump Company series of vertical turbine barge pumps and peripheral equipment provides highly efficient operation to minimize barge unloading times. The pumps are designed for all liquid applications on inland and sea-going barge vessels and work in hydrocarbon applications including distillates, a wide variety of chemical applications and as a ballast control pump for sea-going barges.

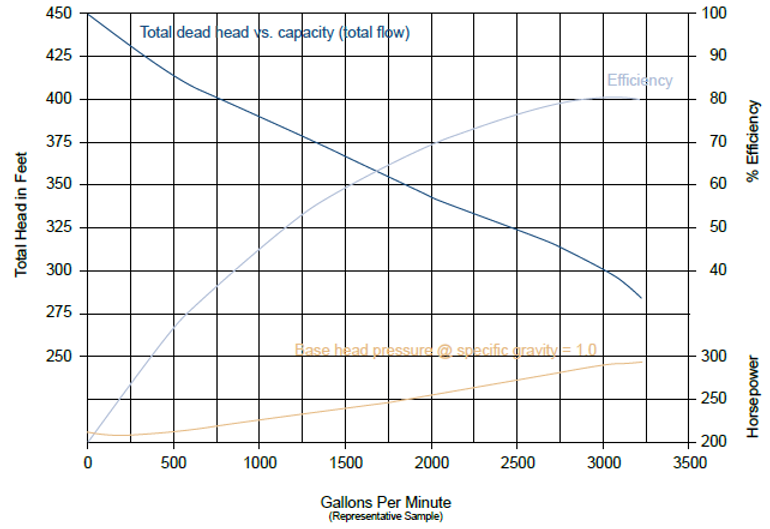

Operating Parameters

-

Typical operating pressure-120 PSI

-

Discharge flanges 8 and 10 inch

-

Flows to 4700 gallons per minute

Pump Operation

-

Priming-At startup, the liquid in the suction inlet is drained into the pump. Vapors are exhausted through the vent tubing into the payload section of the barge.

-

Standard operation-After startup, the bypass and vent valves are closed allowing the pump to function in standard operating mode.

High Quality Construction

-

All ductile construction for increased durability

-

Heavy cast vanes on all ductile steel impellers increases life of impeller

-

Stainless steel split coupling for ease of seal or packing changes

-

Large window in head assembly for easy access to top shaft and seal

-

Custom designed stuffing box with pressure bleed-off line

-

Pre-set cartridge type seal assemblies

-

Heads and gears coated with epoxy and top coated with enamel.

Features

-

Multi-stage design to meet a wide variety of flow and head requirements

-

Stuffing box (packed) with bleed-off

-

Mechanical seal with over bearing adaptor (OBA) for maximum protection of sealing area

-

Self-priming stripper stage with bypass for air and vapors

-

Semi-open impeller design

-

Custom designed discharge head improves onsite servicing of pump seal and hydraulics

-

Contained leakage from stuffing box or mechanical seal

Applications

-

Liquid hydrocarbons including distallates

-

Ballast control for sea-going vessels

Specifications

Design .............. Ductile steel (Bowls and impellers)

Shaft ................. 416 SS-PSQ

Bushings ........... High grade carbon or 660 bronze (Fit for application)

Gaskets ............. Non-asbestos material (Fit for application)

Hardware ........... All stainless steel tubing, fittings, ball valves

Case Study

For additional information on our pumps, please read our case study found in this PDF.