Mining and Drilling

A major international construction firm purchased three Sludge Master pumping systems to be used in their underground tunnel drilling operations. The Sludge Master pumping system is located in the tunnelbore and is used to pump grindings, sand, rock and other solid materials out of the tunnel. The unique abilities of the Sludge Master pumping system make it the only pump that has worked for this application.

Sludge Master Pumping System

What Our Customers Are Saying

"The pumps worked so well for us in Tampa that we bought three more and went to Puerto Rico with them."

-- Charles Keenan Vice President, LARCO

"While I have a minute I thought I would drop you a note about the Sludge Master pump your group revamped for me. Let me start with YOU GOT IT RIGHT! As you know I have been operating Sludge Master pumps since the early 1990’s. The pumps have always been the most reliable heavy sludge pumps we have ever operated. The units have always been easy for field people to operate. The groove clamp design allows the operator to open and clear the checks with 1 wrench in just a matter of minutes. During the revamping of our unit, you were able to combine new technology and old school. Having the unit operate with explosion proof electric allows us to position it next to the tank. The shorter suction means less stress on the pump and more flow. The old school part meant I can keep the poppets. Congrats to you and your staff for another job well done!"

-- JD Crumrine, Allstate Power Va

Specifications

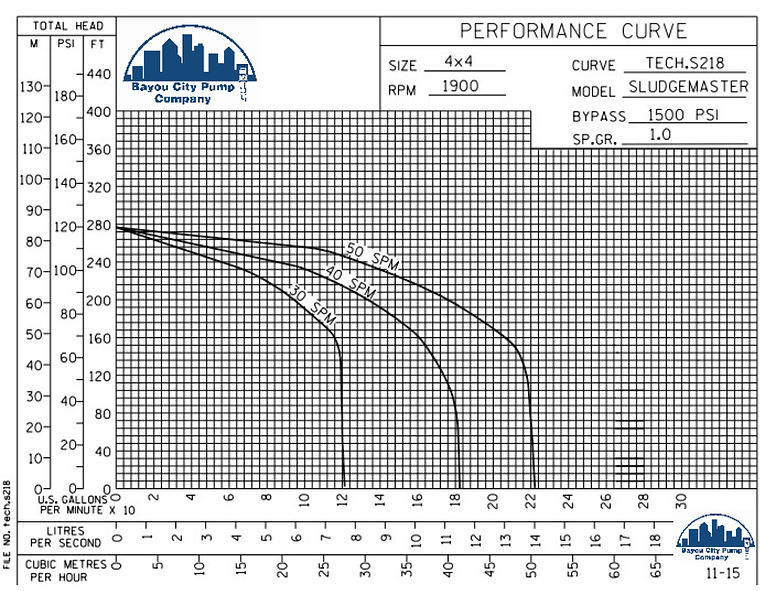

Sludge Master Pump

-

Cast iron and steel construction

-

Sealed ball valve control on each cylinder

-

Dual 12" cylinders capable of moving approximately five gallons per stroke

-

55 strokes-per-minute maximum

-

Viton O-rings throughout

-

Nitrile gaskets and polymite packed seals on cylinders and valves

-

4" inlet/discharge

-

Approximately 1,000lbs., 73"Wx24"Dx37"H

Hydraulic Power Unit

-

33 HP diesel engine with 55 gallon fuel tank or 30 HP electric motor

-

60 gallon hydraulic oil reservoir

-

Skid or trailer mounted, ready for trailer mount

-

Hydraulic oil cooler

-

Flow control valve

-

Hydraulic pressure relief valve

Environmental

The Sludge Master pumping system has met a lot of environmental challenges, including tank cleaning jobs and small oil spills.

The Sludge Master pumping system was used as an integral part of a submerged oil cleanup job near Tampa, Florida. Based on its superior performance additional units were purchased for the 600,000 gallon oil spill off the coast of San Juan, Puerto Rico.

In addition the pump was an essential component in the cleanup of a superfund site in South Houston. Hydrocarbon based heavy sludge had been dumped at the site by local chemical plants. A total of six Sludge Master pumping systems were used for six months to clean the site. The Sludge Master was the only pumping system used that could remove the heavy sludge material without fouling or damaging the pump.

Process

A refinery in Texas City used the Sludge Master pumping system to pump heavy slurry into a filter press. The filter press removes impurities from a chemical mixture. The Sludge Master pumping system was selected because the discharge pressure of the pump could be adjusted to hold a constant pressure. This self adjusting capability is achieved by a load sense feature designed into the hydraulic power system.

The Sludge Master pump passes solids such as rags, rocks, nuts, bolts, Tyvec suits, rubber gloves, rope and more without damage to the system and is designed to operate while pumping hazardous chemical materials.

Bayou City Pump Company manufactures a specialty pumping system, the Sludge Master, designed and developed by our company. This hydraulically-driven, piston pumping system is designed to pump heavy sludges, slurries and other viscous materials that contain solids and impurities. The pumping system has a flow rate up to 250 gallons per minute. The self-priming Sludge Master, which is virtually leak proof, can dry run for a limited time without damage. It features low maintenance with no diaphragms that can burst under pressure or mechanical seals to fail.

The integral hydraulic power unit is custom designed to drive the Sludge Master's reciprocating pistons. The hydraulic power unit includes the engine (diesel or electric), hydraulic reservoir, hydraulic control unit, oil cooler and interconnecting hoses. The hydraulic power unit can be located remotely, as far as 150 feet from the Sludge Master pump.

Features

-

Steel construction

-

Flows to 250 GPM

-

Solids handling

-

Discharge pressure up to 150 PSI

-

Anti-clog ball valve design

-

Adjustable flows and pressures

-

Self troubleshooting valves

-

Self-priming - pulls full vacuum

-

Low maintenance

-

Mobile, lightweight

Applications

-

Chemicals

-

Environmental, pit cleaning

-

Oil spill response

-

Wastewater

-

Filter cakes

-

Pulp and paper, rail car

-

Viscous materials

-

Sludge injection

-

Paint and hazardous sludges

-

Crude and #6 oil (bottoms)

-

Tank bottom sludges

-

Special processes

-

Slurries

Owner's Manual

Please click the button below to download the Sludge Master's updated manual

Safety Features

-

Hydraulic pressure relief valve

-

Sludge Master discharge pressure switch

-

Hydraulic reservoir low fluid safety switch

-

Engine panel equipped with safety features to protect the

engine from low oil pressure and high coolant temperature